SAFE

WORKING AT HEIGHT

Oleh : Bayu Nurwinanto

The purpose of this

manual is to eliminate potential harm to all employees, contractors and

visitors . resulting from persons falling from one level to another or being

affected by falling objects. It applies to :

- All operating sites and offices.

- All employees, contractors and visitors.

The manual requires

that a system of work for prevention of falls from height is established and

maintained in all work situations. This can be achieved through :

- Where practicable, the elimination of the need to work where there is the risk of a fall.

- Conducting risk assessments before the commencement of work and at any time the scopeof work changes or the risk of a fall increases.

- Selection of appropriate control measures using the hierarchy of controls.

- Ensuring all equipment used is fit for work.

- Ensuring all persons responsible for, or performing work, where there is a risk of falling, are competent in the correct use of the site management systems for the prevention of falls.

- Development of procedures for the use and disposal of all equipment that supports or lifts a person at height.

- The use of fall arrest equipment as the last option for a control measure (after all other control measures have been explored and deemed to be inappropriate), where it is not practicable to eliminate the risk of a fall.

WORK AT HEIGHT

“Work at Height” is

defined as whenever people are at risk of falling from, into or through one level

to another. No minimum height is stipulated as to when controls must be

implemented. If a person can fall from one level to another a risk assessment

must be completed.

FALL INJURY

PREVENTION SYSTEMS (FIPS)

Fall Injury Prevention Systems are systems

designed to arrest or prevent a person falling from one level to another,

whilst minimising the risk of injuries or harm during the fall. FIPS include

fall restraint systems, fall arrest systems, catch platforms, scaffolding,

safety nets and safety mesh.

RESTRAINT TECHNIQUE

A combination of anchorage placement and lanyard

length adjustment which will not physically permit the operator to reach a

fall-risk position unless the lanyard is incorrectly adjusted.

|

(A) Restraint technigue adjustable lanyard

|

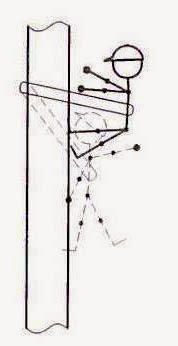

RESTRAINED FALL

A pole-strap of length

which will permit only a restrained fall when working on a pole.

|

(B) Restraint Fall Polestrap

|

LIMITED

FREE FALL

A combination of anchorage placement and lanyard

length which will permit only a limited free fall (≤600 mm).

|

(C) Limited Fall-Free distance ≤ 600

|

FREE FALL

Equip operators with personal fall-arrest

equipment which will not prevent a fall but minimise the risk of injury in the

event of a fall, maximum 2 metres free fall. This will likely involve static

lines or lanyards with shock absorbing devices.

|

(D) Free fall-free fall distance >600

|

ANCHORAGE

POINT

A secure point of attachment on a structure to

which a safety harness or fall restraint / fall arrest device, or lanyard, or

lanyard assembly or static line may be secured.

SAFETY HARNESS

A full body harness

with a fall arrest attachment point at the top dorsal position, i.e. between shoulder

blades, which was manufactured and complies with AS1891.1 Industrial Fall

Arrest Systems and Devices - Safety Belts and Harnesses.

LANYARD

A lanyard is used to

connect a safety harness to an anchorage point or static line in situations

where there is a risk of a fall or when used in restraint mode to prevent a

fall. Lanyards can be either adjustable or fixed length and incorporate the use

of a shock absorber.

STATIC LINE (PERMANENT OR TEMPORARY)

A horizontal safety line or rail system to which

a lanyard may be attached and which is designed to arrest a free fall, as per

AS 1891.2 Industrial Fall Arrest Systems and Devices - Horizontal Lifeline and

Rail Systems.

TRAINING AND

COMPETENCY

All Team Leaders, Responsible Officers and

employees working at heights; or responsible for work carried out where there

is a risk of falling shall be competent in the correct use of the systems for the

prevention of falls.

Persons who are

exposed to the risk of falling shall:

- Be able to participate in the risk assessment of the work.

- Know and understand the control measures for fall prevention.

- Be competent in the correct use of those control measures e.g. All PPE and equipment.

- Have a current license, ticket or certificate of competency for any plant being used as a

- control measure e.g. EWP, scaffold etc.

OTHER RELATED TRAINING

Equipment training

linked to working safely at heights can include :

- Mobile Work Platforms.

- Scaffoldings.

- Rigging & Dogging.

RISK

ASSESSMENT

All persons required to perform work at

height must understand and actively participate in risk management processes.

HIERARCHY OF CONTROLS

Users of fall prevention equipment need to be

aware how these systems are placed within the hierarchy of control for fall

prevention, so that an assessment can be made as to whether the highest level

of practical protection practical is being applied in case. The hierarchy of

controls are.

Elimination - Eliminate the need to access

the fall-risk area, e.g. by locating and selecting items requiring inspection,

maintenance and other attention, elsewhere.

Substitution - Provide alternative means of

access to the point or item to which access must be made which avoids the risk

of a fall e.g. walkways or scaffolding.

Engineering / Isolation - Barricade or

enclose the fall-risk so that it cannot be reached by, hard bunting, handrail

scaffolding.

Administrative controls are required for all

steps; JSA’s or SOP, SWP for common tasks, training, signs etc.

Fall Prevention PPE - Must only be considered

as a last resort and only if all other control measures are impracticable,

unavailable or will introduce further hazards to the work. Provide PPE which

either prevents a fall or reduces risk or severity of a fall.

Persons shall calculate the actual distance

based on the equipment they will use prior to its use Figure for example :

ANCHOR POINTS

Anchor points are used to

attach Fall Arrest harness worn by a person via a connecting lanyard. Anchor

points used in Fall Injury Prevention Systems (FIPS) shall be assumed to

withstand the force of the load if a person was to fall. Anchor points for limited

or free fall.

- Shall be located above head height of the person and located in a central location (within 30 degrees from vertical) that prevents a pendulum swing.

- Shall have the required clearance below the worker for the type of system being employed (eg length of lanyard, plus tear out distance, height of user plus safety margin).

- Shall consist of a closed loop hook eye and must allow for the direct attachment of the safety device. Alternately, an endless loop lanyard can be wrapped around a suitable size steel structure (capable of holding 1500Kg) and the lanyard directly connected to both ends of the endless loop lanyard. Do not choke the endless loop lanyard.

- Can be a “Static Line” as long as it has been correctly designed and installed.

- Can be scaffold if correctly designed to be on anchor point.

- Pre-use inspection by the user.

- For permanent anchors in general areas a six (6) monthly formal, certified integrity check that is recorded.

Static lines are used

where a range of movement is required in one direction. A typical example being

when repairing or painting a roof where free movement along the roof is

required but persons need to be prevented from falling off the edge of the

roof. Static lines can be used as anchor points for either fall restraint or

fall arrest equipment.

They shall be either :

- Permanent 12mm diameter steel (generally stainless steel) cable attached to permanent anchors or;

- Temporary systems that use 20 mm diameter flexible rope that is suitable for such use. Natural fibre rope shall not be used.

Anchor points for

static lines shall be designed, approved and checked after installation by a

structural engineer.

A number of

commercial temporary static line systems are available which include attachment

and tensioning devices. Only those systems that comply with AS1891 shall be

used.

Maintenance of static

lines will depend on its frequency of use and where it is used. However, the

following is required:

- Pre-use inspection by the user.

- For permanent static lines a formal certified integrity check of the cable and anchors shall occur every six months and be recorded and the line tagged. Greater inspection frequency shall occur in aggressive environmental conditions.

- For temporary static lines, all components shall be checked prior to use, paying particular attention to any fraying, cracking or cuts in the rope be recorded and the line tagged. The attachments shall be checked for distortion, cracks or sharp edges where the rope contact occur.

- Emergency response coordinators shall be informed of each use of a static line system.

Lanyards are used to connect persons who are wearing either fall restraint or arrest equipment to an anchor point. There are several types, being fixed length, shock absorbing and inertia reel

retractable, which are detailed in the section below.

Those using a lanyard shall ensure that it is suitable for the proposed use and that it will provide the required fall restraint or arrest. All fall arrest situations shall require a shock absorber in the system.

Fixed length lanyards are used in either fall restraint or arrest situations. For fall restraint, the length needs to be such that, at maximum length, it prevents the person getting too close to any edge where the person could fall. For fall arrest, the summed length of the lanyard, the expanded shock absorber, the person and a one (1) metre safety margin, does not exceed the height that the person can fall.

Shock absorbing lanyards can be used in either total restraint or free fall arrest situations. Endless loop lanyards (snake slings) are used to wrap around structural beams etc. in order to provide an anchor point for either fall restraint or arrest. An endless loop lanyard shall not be choked (one end threaded through the other) rather both ends shall be placed in the attachment device of the attaching lanyard.

Lanyards must be

checked for compatibility of all components, including the harness attachment

point and anchor attachment point which must be with a Double Action Steel

Screw Gate type Karabiner to prevent the potential for either ‘Crush out’ or

‘Rollout’ occurring.

All lanyards, with the exception of the endless loop, shall be fitted with Double Action Steel screw gate karabiners. It is important to inspect the work area where the lanyards will be used to ensure that they will not be damaged by sharp edge on beams or sheet steel, dangle in pools of water, oils or chemicals and the karabiners do not become jammed up with dust or crushed rock.

Any Carabiners that are unable to be fully screwed closed shall be replaced immediately.

Maintenance on lanyards shall be :

- Pre-use visual inspection for cuts, abrasion, heat or oil or chemical damage and currency of operating life, which shall not exceed ten years from manufacture.

- Pre-use check of the condition of carabiners to ensure that they operate freely, do not jamb open and are not bent or damaged in any manner.

- For shock absorbing lanyards, a pre-use check that the shock absorber has not opened in any manner indicating that it has arrested a fall.

- A six monthly formal, certified integrity check by a registered organisation that shall be recorded and the lanyard tagged with date of inspection. This will be organised by the Emergency Services Coordinator in conjunction with Area Planners.

They are particularly suitable where good flexibility in a working area is required. They are advantageous where persons climb up and down a structure as part of their work tasks. They are also useful for low height fall arrest situations where other types of shock absorbers cannot be used.

Persons using an inertia reel lanyard shall :

- Conduct a pre-use inspection of the whole length of the inertia reel, checking for cuts and tears on fibre type and damaged, “bird caged” or broken wires on wire type device.

- Check the inspection tag to ensure that a formal inspection has occurred within the last 3 months.

- Check for damage on the housing and cable or fibre entry point.

- Check for the correct and immediate operation of the locking device when a quick pull is applied to it.

- A formal and documented inspection every three months conducted by a competent person.

- Annually an internal inspection of the device by an authorised service agent (in the absence of recommendations specified by the manufacturer) shall occur.

- Tagging and recording (log record) of the device to indicate that the inspection has occurred.

|

| Figure 1 |

|

| Figure 2 |

That’s great! Just pumped up. You always give your best!

ReplyDeleteSuper useful and awesome information here. I thank you! Thank you very much!

Have a look at our website to buy safety equipment's if you want.

Fall Arrest Harness and Lanyard

Slot City Casino: 70 Free Spins on Slots of Vegas - Mapyro

ReplyDeleteSlot 문경 출장샵 City is 경산 출장마사지 a fun and 나주 출장샵 fun casino that has been 포항 출장샵 around since 2012 and with a fantastic 영주 출장마사지 range of slots, jackpots and promotions.

Having a great training work safety should always be a priority among company owners. Than you for being such a great source for work safety resources and definitely I am learning a lot from you. I also found Executive Training School as great school that helps you get RIIWHS204E work safely at heights certificate.

ReplyDelete