INSPECTION PRESSURE VESSEL PRACTICES

Oleh : Bayu Nurwinanto

PREPARATORY WORK

Safety precaution are important in pressure vessel inspection because of the limited access to and the confined spaces. Occupational safety and Health Administration (OSHA) regulation pertaining to confined spaces and any other OSHA safety rules should be reviewed and followed, where applicable.

For an internal inspection, the vessel should be isolated by blinds or other positive methods from all sources of liquids, gases, or vapors. the vessel should be drained, purged, cleaned, ventilated, and gas tested before it is entered. Where required, protective equipment should be worn that will protect the eyes, lungs, and other parts of the body from specific hazards that may exist in the vessel.

The non-destructive testing equipment used for the inspection is subject to the safety requirements customarily followed in a gaseous atmosphere. Before the inspection is started, all person working around the vessel should be informed that people are going to be working in side it. People working inside the vessel should be informed when any work is going to be done on the exterior of it.

The tools and personeel safety equipment needed for the vessel inspection should be checked before the inspection. Other equipment that might be needed for the inspection, such as planking, scaffolding, bosun's chairs, and portable ladders, should be available if needed.

MODES OF DETERIORATION AND FAILURE

Contaminants in fluids handled in pressure vessels, such as sulfur, chlorine, hydrogen sulfide, hydrogen, carbon, cyanides, acids, water, or other corroding species may react with metals and cause corrosion. Significant stress fluctuations or reversals in part of equipment are common, particularly at points of high secondary stress. If stresses are high and reversals are frequent, failure of parts may occur because of cyclic temperature and pressure changes. Locations where metals with different thremal coefficients of expansion are welded together may be susceptible to thermal fatigue.

Deterioration or creep may occur if equipment is subjected to temperatures above those for which it is designed. since metals weaken at higher temperatures, such deterioration may cause failures, particularly at points of stress concentration. Creep is dependent on time, temperature, stress, and material creep strength, so the actual or estimated levels of these quantities should be used in any evaluations. At elevated temperatures, other metallurgical changes may also take place that may permanently affect equipment.

For developing an inspection plan for equipment operating at elevated temperatures generally starting in the range of 750 - 1000 F (400- 540 C), depending on operating conditions and alloy, the following should be consideredd in assessing the remaining life :

- Creep deformation and stress rupture.

- Creep crack growth

- Effect of hydrogen on creep.

- Interaction of creep and fatigue.

- Possible metallurgical effects, including a reduction in ductility

Numerous NDE techniques can be applied to find and characterize elevated temperature damage, These techniques include visual, surface, and volumetric examination. additionally, if desired or warranted, samples can be removed for laboratory analysis.

The inspection plan should be prepared in consultation with an engineer having knowledge of elevated temperature and metallurgical effect on pressure vessel material of construction. At subfreezing temperatures, water and some chemicals handled in pressure vessels may freeze and cause failure.

At ambient temperature, carbon, low-alloy, and other ferritic steel may be susceptible to brittle failure. A number of failures have been attributed to brittle fracture of steels that were exposed to temperatures below their transition temperature and to pressure greater than 20 percent of the required hydrostatic test pressure; most brittle fractures, however, have occurred on the first application of a particular stress level (the first hydrotest or overload). Although the potential for a brittle failure because of excessive operating conditions below the transition temperature shall be evaluated, the potential for a brittle failure because of rehydrotesting or pneumatic testing of equipment or the addition of any other additional loadings shall also be evaluated. Special attention should be given to low-alloy steels (especialy 21/4 Cr-I Mo) because they may be prone to temper embrittlement. Temper embrittlement is a loss of ductility and notch toughness due to postweld heat treatment or high-temperature service (above 700 F) (370 C).

CORROSION RATE DETERMINATION

For a new vessel or for a vessel for which service conditions are being changed, one of the following method shall be employed to determine the vessel's probable corrosion rate. The remaining wall thickness at the time of the next inspection can be estimated from this rate.

- A corrosion rate may be calculated from data collected by the owner or user on vessel providing the same or similar service.

- If data on vessel providing the same or similar service are not available, a corrosion rate may be estimated from the owner's or user's experience or from published data on vessels providing comparable service.

- If the probable corrosion rate cannot be determined by either item a or item b above, on- stream determinations shall be made after approximately 1000 hours of servece by using suitable corrosion monitoring deveces or actual nondestructive thickness measurements of the vessel or system. Subsequent determinations shall be made after appropriate intervals until the corrosion rate is established.

If it is determined that an inaccurate corrosion rate has been assumed, the rate to be used for the next period shall be increased or may be decreased to agree with the actual rate.

DEFECT INSPECTION

Vessels shall be examined for visual indications of distortion. If any distortion of a vessel is suspected or observed, the overall dimensions of the vessel shall be checked to confrim whether or not the vessel is distorted and, if it is distorted, to determine the extent and seriousness of the distortion. the pats of the vessel that should be inspected most carefully depend on the type of vessel and its operating conditions. The authorized pressure vessel inspector should be familiar with the operating conditions of the vessel and with the causes and characteristics of potential defects and deterioation.

Careful visual examination is the most important and the most universally accepted method of inspection. Other methods that may be used to supplement visual inspection include.

- Magnetic-particle examination for cracks and other elongated discontinuities in magnetic material;

- Fluorescent or dye- penetrant examination for disclosing cracks, porosity, or pin holes that extend to the surface imperfections, especially in non-magnetic material.

- Radiographic examination;

- Utrasonic thickness measurement and flaw detection;

- Eddy current examination;

- Metallographic examination;

- Acoustic emission testing; hammer testing while not under pressure;

- Pressure testing (Section V of the ASME Code can be used as a guide for many of the nondestructive examination techniques).

Adequate surface preparation is important for proper visual examinations and for the satisfactory application of any auxiliary procedures, such as those mentioned above. The type of surface preparations required depends on the individual circumstances, but surface preparations such as wire brushing, blasting, chipping, grinding, or a combination of these preparations may be requred.

If external or internal covering, such as insulation, refractory protective linings, and corrosion-resistant linings, are in good condition is behind them, it is not necessary to remove them for inspection of the vessel; however it may be advisable to remove small portions of the coverings to investigate their condition and effectiveness and the condition of the metal underneath them.

Where operating deposits, such as coke, are normally permitte to remain on a vessel surface, is is particularly important to determine whether such deposits adequately protect the vessel surface from deterioration. To determine this, spot examinations in which the deposit is thoroughly removed from selected critical areas may be required.

Where vessel are equipped with removable internals, the internal need not be remove completely as long as reasonable assurance exists that deterioration in regions rendered inaccessible by the internals is not occurring to an extent beyound that found in more accessible parts of the vessel.

PRESSURE TEST

When the authorized pressure vessel inspector believes that a pressure test is necessary or when, after certain repairs or alterations, the test shall be conducted at a pressure in accordance with the construction code used for determining the maximum allowable working pressure. to minimize the risk of brittle fracture during the test, the metal temperature should be maintained at least 30 F (17 C) above the minimum design metal temperature for vessel that are more than 2 inches (5 centimeters) thick, or 10 F (6 C) above for vessel that have a thickness of 2 inches (5 centimeter) or less. The test temperature need not exceed 120 F (50 C) unless there is infoemation on the brittle characteristics of the vessel material indicating that a lower test temperature is acceptable or a higher test temperature is needed.

Pneumatic testing may be used when hydrostatic testing is impracticable because of temperature, foundation, refractory lining, or process reasons; however, the potential personnel and propety risks of pneumatic testing shall be considered before such testing is carried out. As a minimum, the inspection precautions contained in the ASME Code shall be applied in any pneumatic testing. Before applying a hydrostatic test to equipment, consideration should be given to the supporting structure and the foundation design.

When a pressure test is to be conducted in which the test pressure will exceed the set pressure of the safety relief valve with the lowest setting, the safety relief valve or valves disks. Applying an additional load to the valve spring by turning the compression screw is not recommeded. Other appurtenances such as gauge glasses, pressure gauges, and repture disks, that may be incapable of with standing the test pressure should also be remove or should be blanked off or vented. When the pressure test has been completed, pressure relief devices of the proper setting and other appurtenances remove or made inoperable during the pressure test shall be reinstalled or reactivated.

PRESSURE RELIEVING DEVICES

Pressure relief valves shall be tested and repaired by repair organizations experienced in valve maintenance. Each repair organization shall have a fully documented quality control system. As a minimum the following requirements and pieces of documentation should be included in the quality control System :

- Title page.

- Revision log.

- Contensts page

- Statement of authority and responsibility.

- Organizational chart.

- Scope of work.

- Drawings and specification controls

- Material and part control.

- Repair and inspection program.

- Welding, nondustructive, and heat treatment procedures.

- Valve testing, setting, leak testing and sealing.

- General example of the valve repair name plate.

- Procedures for calibrating measurement and test gauges.

- Controlled copies of the manual.

- Sample forms.

- Repair personnel training or qualifications.

Each repair organization shall also have a fully documented training program that shall ensure that repair personnel are qualified within the scope of the repairs. Pressure relief valves shall be tested at interval that are frequent enough to verify that the valve perform reliably. This may include testing pressure relief valve on newly installed equipment. Pressure relieving devices should be tested and maintained in accordance with API Recommended Practice 576. Other pressure relieving devices, such as rupture disks and vacuum breaker valves, shall be thoroughly examined at intervals determined on the basis of service.

The intervals between pressure-relieving device testing or inspection should be determined by the performance of the devices in the particular service concerned. Test or inspection intervals on pressure relieving devices in typical process services should not exceed 5 years, unless service experience indicates that a longer interval is acceptable. For clean (nonfouling), noncorrosive service, maximum intervals may be increased to 10 years. When service records indicate that last inspector or test, the service interval shall be reduced if the review show that the device may not perform reliably in the future. The review should include an effort to determine the cause of fouling or the reasons for the relief device not operating properly.

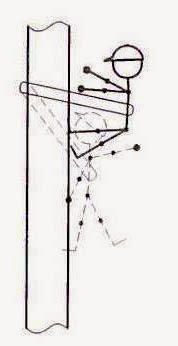

SAMPLE DRAWING

|

| HORIZONTAL RETENTION TANK |